ENCLOSE®

ENCLOSE® is a lightweight, yet tough expandable woven sleeving product ideal for electrical wire harnessing situations where removal and re-installation is common. It offers the unique feature of a seamed design that allows for installation over connectors or fittings and is perfect in applications where junctions and wire breakouts are inevitable. It is rated to 125°C and ensures bundle integrity and wire protection from environments with high abrasion or trapped moisture.

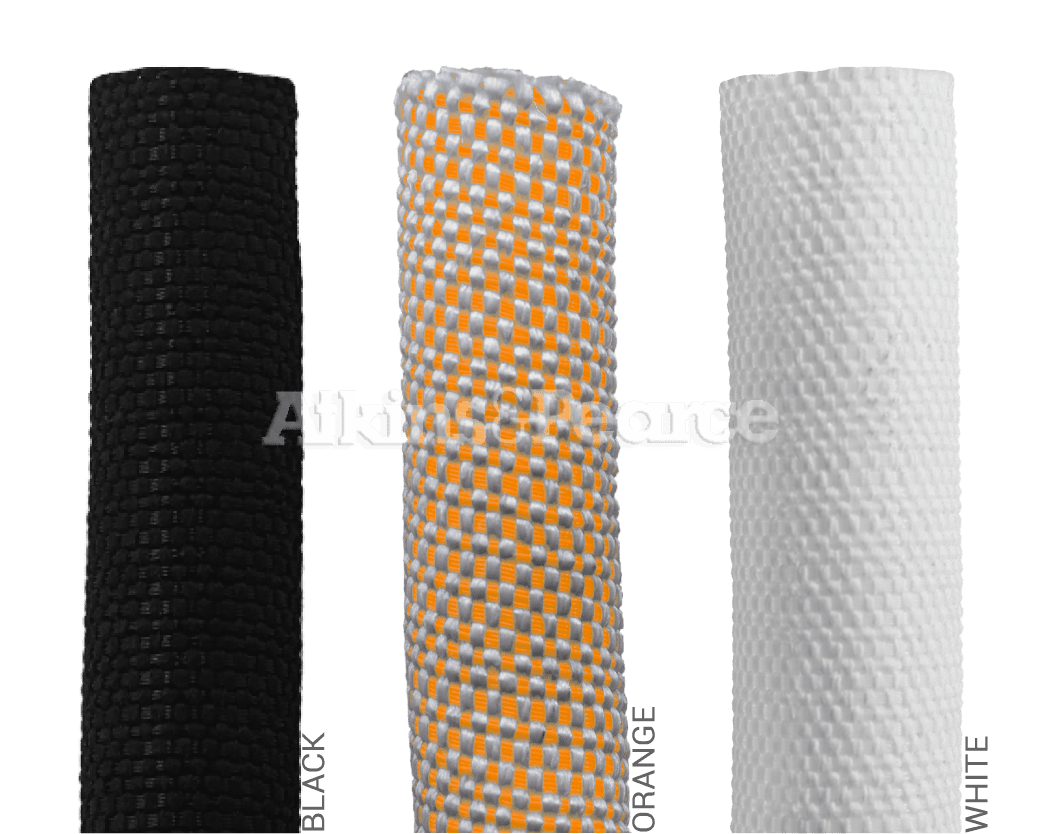

Currently we only offer ENCLOSE® for online purchase in black; however, we do manufacture other colors. If you are interested in exploring other colors, please contact us for assistance. All 25 FT lengths offered online are splice-free.

Features of ENCLOSE®

- Offers a seamed design for easy removal and re-installation over connectors/fittings

- Maximum Operating Temperature: 125°C / 257°F

- UL Temperature and Horizontal Flame Rated (File #E118600)

- CSA Temperature and FT2 Rated

- Available in several colors

- REACH and RoHS Compliant

- Wrappable, serviceable entry ensures bundle integrity and protects wires from abrasion and trapped moisture

Download ENCLOSE® Datasheet

Testing Data for ENCLOSE®

| PROPERTY | TEST | VALUE |

|---|---|---|

| Abrasion | ASTM D-4060 | 3,000 cycles |

| Heat Age @ 168 Hours | ASTM D-3045 | No Cracking, Melting, or Deformation |

| Low Temperature Flexibility | Below Freezing | No Cracking or Deformation |

Temperature Scale for ENCLOSE®

| PROPERTY | VALUE |

|---|---|

| Maximum Operating Temperature | 125°C / 257°F |

| Melting Point | 250°C / 482°F |

Monofilament Properties of ENCLOSE®

| PROPERTY | VALUE |

|---|---|

| Single-Strand Diameter | 0.010" |

| Density | 1.38 g/cc |

| Single-Strand Tensile Strength | 8.5 lbs. |

| Moisture Absorption | 0.20% |

DISCLAIMER

The suggested application is provided by Atkins & Pearce merely as an additional tool to assist the customer in making an appropriate expandable sleeving selection. This is only provided to serve as suggestions of expandable sleeving that may be appropriate based on certain criteria and should not be relied upon as determinative or as a substitute for customer testing.

Many variables exist in a sleeve’s flexibilities, resistances, and treatment. Final sleeving product selection should always be confirmed through the customer’s own testing process to determine if a particular product is the correct choice for a particular system. Atkins & Pearce is not responsible for selections made by the customer using any of the reference material provided. For optimal performance in specific systems, we strongly recommend that customers conduct exhaustive electrical tests in their own lab and consider retaining samples for their future internal reference. The importance of expandable sleeving product testing and data validation cannot be overstated.

As the customer, you and your company are responsible for appropriately testing all Atkins & Pearce expandable sleeving used in your application and for making the final selection based upon meeting appropriate safety and electrical standards. Atkins & Pearce makes no representation or warranty, expressed or implied, at law or in equity, in respect of the information provided, including, without limitation, with respect to merchantability or fitness for any particular purpose, which representations or warranties are hereby expressly disclaimed.

Product Spotlight Video