MONOFLEX® HT

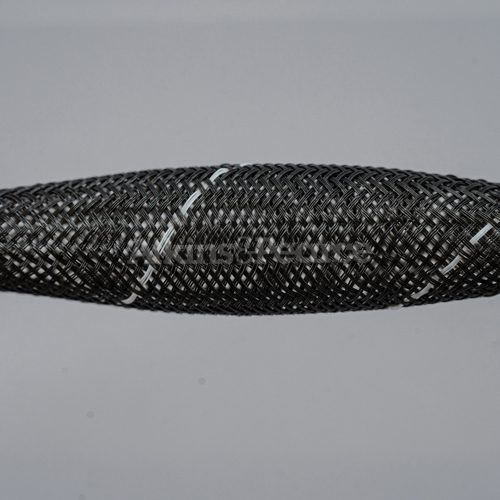

MONOFLEX® HT is an unique expandable sleeving offering made of ethylene chlorotrifluoroethylene (ECTFE) ideal for applications where flammability, impact strength endurance, and low outgassing are primary concerns. This self-extinguishing and flame resistant sleeving exhibits low outgassing and has high impact strength. It’s low flame spread and low smoke generation properties make it an ideal sleeving for plenum applications.

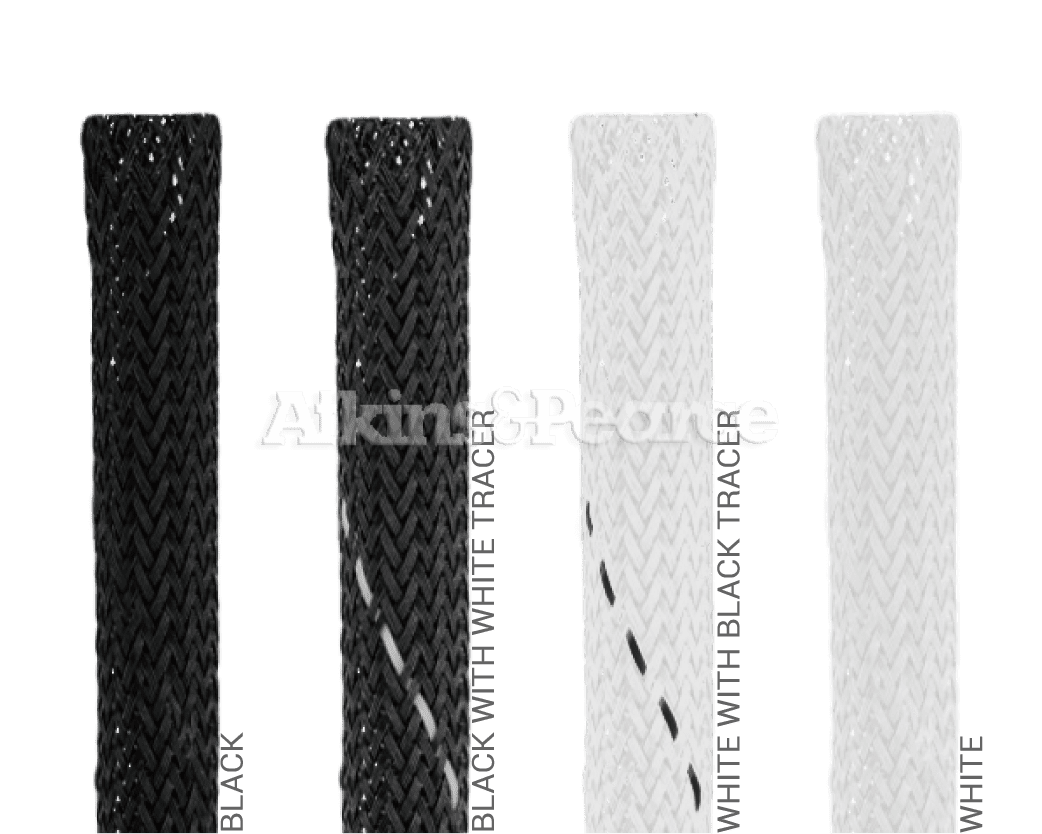

MONOFLEX® HT is currently unavailable for purchase online; please reach out through the button below for purchasing assistance from our Sales & Marketing Team or to learn more about the color variety and multiple sizes we offer.

Features of MONOFLEX® HT

- Maximum Operating Temperature: 150°C / 302°F

- Good abrasion resistance

- REACH and RoHS Compliant

- UL Temperature Rated (File #E118600) and CSA Temperature Rated

- UL VW-1 Rated (File #E118600) and CSA FT1 Rated

- Self-Extinguishing and Flame Resistant

- Direct match to Alta Technologies Flex-Guard™ H (954 series)

Testing Data for MONOFLEX® HT

| PROPERTY | TEST | VALUE |

|---|---|---|

| Abrasion | ASTM D-4060 | 7,500 cycles |

| Hardness (Shore D) | ASTM D-2240 | 75 |

| Limiting Oxygen Index | ASTM D-2863 | 52% |

| Low Temperature Flexibility | Below Freezing | No Cracking or Deformation |

Temperature Scale for MONOFLEX® HT

| PROPERTY | VALUE |

|---|---|

| Maximum Operating Temperature | 150°C / 302°F |

| Melting Point (ASTM D-3418) | 242°C / 467°F |

Monofilament Properties of MONOFLEX® HT

| PROPERTY | VALUE |

|---|---|

| Single-Strand Diameter | 0.011" |

| Density (ASTM D-792) | 1.68 g/cc |

| Moisture Absorption (ASTM D-570) | < 0.1% |

| Outgassing | Low Outgassing |

| Single-Strand Tensile Strength | 2.7 lbs. (minimum) |

DISCLAIMER

The suggested application is provided by Atkins & Pearce merely as an additional tool to assist the customer in making an appropriate expandable sleeving selection. This is only provided to serve as suggestions of expandable sleeving that may be appropriate based on certain criteria and should not be relied upon as determinative or as a substitute for customer testing.

Many variables exist in a sleeve’s flexibilities, resistances, and treatment. Final sleeving product selection should always be confirmed through the customer’s own testing process to determine if a particular product is the correct choice for a particular system. Atkins & Pearce is not responsible for selections made by the customer using any of the reference material provided. For optimal performance in specific systems, we strongly recommend that customers conduct exhaustive electrical tests in their own lab and consider retaining samples for their future internal reference. The importance of expandable sleeving product testing and data validation cannot be overstated.

As the customer, you and your company are responsible for appropriately testing all Atkins & Pearce expandable sleeving used in your application and for making the final selection based upon meeting appropriate safety and electrical standards. Atkins & Pearce makes no representation or warranty, expressed or implied, at law or in equity, in respect of the information provided, including, without limitation, with respect to merchantability or fitness for any particular purpose, which representations or warranties are hereby expressly disclaimed.